Another interesting stained glass challenge recently was the creation of one new stained glass window out of two old stained glass windows that were still in their wooden window frames. The two panels looked very similar at first glance, but they were different sizes and had different green glasses for the leaves – and also different background glasses.

The client wanted the best parts of each to be reused for a new window to block an unsightly view. It would stand in a bespoke base support on the window sill next to the existing sealed unit double glazing and be clipped at the top via steel loops.

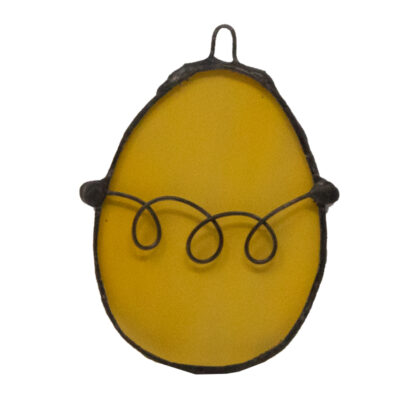

Based upon our discussions, I set about designing a new top section and a double border in clear and pale yellow textured glasses. I wanted to balance out the design and colours between the top and bottom sections, reusing the existing glasses as much as possible.

The client approved the new design, so the panels were removed from the frames as carefully as possible. This is not an easy job when there are layers of paint built up over the years. It is a delicate operation to remove the old glass and lead intact without damage. Once the panels were out of their frames, they were a lot less structurally sound and a lot of the old putty crumbled and fell out from under the leads.

I carefully removed the edge glass pieces and set about building the new central panel with leftover glass from the bottom panel reused as the background for the new top section. New lead strips were added where necessary and some of the leaves were moved and redesigned. I added a sliver of red in the top section to balance with the one in the bottom part. There was very little room for error as the clear glasses are no longer made and I only had the border pieces to work with. Happily, I was able to build the centre section successfully. Then I had a similar worry with the clear glass border, which was made from leftover glass from the top panel. Again, though, I managed to cut all the pieces accurately. Thankfully, I had plenty of the new yellow border glass for the outside edge.

Steel strips were added within the leads to improve the rigidity of the structure and zinc cames were used for the surround for extra strength. Then it was the usual messy job of filling the gaps on both sides with fresh lead light cement, to support the integrity of the old areas and tone with the new areas. Next it was cleaning, blacking the leads and cleaning again. There is a lot of cleaning involved in stained glass window production! And of course you have to do both sides…

While it could have been quicker to start fresh and make this whole design from new materials, it is satisfying to give old glass, with its unique textures and qualities, a new lease of life in a refreshed design that works very well in a contemporary setting. Upcycling at its best!

0 Comments